S-Twist denotes the direction of twist, to the left looking up, in a single thread or

folded yarn.

Opposite of

Z-Twist. The amount of twist is measured in turns per unit length of the yarn. e.g. turns per inch; turns per 100cm.

The firm SACM was a loom manufacturer, based in Mulhouse, the second largest city in the Alsace region of France after Strasbourg.

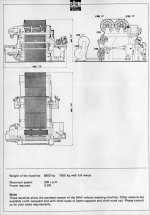

John Holdsworth & Co Ltd purchased one SACM double rapier loom, model MAV-velours weaving machine, type 180/R with maximum running speed of 200 rpm in 1975. Weft insertion by cam-driven rapiers operated on the Dewas principle, by tip transfer.

This loom was not as effective as the

Güsken loom, and was found to have several fundamental omissions in its design, and was comparatively noisy. Particularly after delivery and installation, new guards had to be constructed and fitted to cover exposed moving parts and comply with basic safety requirements.

|

|

|||||

|

|

|

|

|

|

St John's Church, Warley, 15 Oct 2008

St John's Church, Warley, 15 Oct 2008Located on Windle Royd Lane, a short hill off Burnley Road, Halifax, HX2 7LW.

Tel: 01422 363623

John Holdsworth & Co Ltd is situated in the Parish of

St. Mark's, Siddal which was previously part of the

Parish of All Saints’, Salterhebble.

The Holdsworth family and many of the workforce have long associations with the school, the church and the parish.

See the page on

Saint Mark’s Church, Siddal

Saint Mary’s Church, Illingworth, Halifax is located above the position of the (now demolished 2009) "Talbot Inn" on the Keighley Road in Illingworth, to the north of Halifax, and dates from 1525.

It was rebuilt in 1777.

A number of the Holdsworth family were laid to rest there in the 18th century, at a time when they lived in and around Northowram.

"Abraham offering up his son Isaac," a memorial window, was the gift of

Mr. Tom Holdsworth of

Spring Hall.

"Raising the Widow’s Son" and "The Agony in the Garden", two windows erected, one by Lieut.Co. Holdsworth and the other by Mrs Holdsworth.

Scargill House, the Holdsworth family residence, is situated in the Parish of Kettlewell, one of the largest parishes in Yorkshire.

The Holdsworth family have been associated with the church and village community since 1900, with commemorative stained glass windows, the lychgate and there is a family grave in the churchyard.

See the page on Saint Mary’s Church, Kettlewell

St. Oswald’s Church, Arncliffe is the early 12th century church where Kirsten Holdsworth was christened in 1953.

This is not far from the family's home at the time,

Scargill House, near

Kettlewell.

The tower houses a set of 3 bells; the oldest was cast by Johnannes de Stafford ca.1350; youngest by Thomas Mears in 1842, and the tenor, 15cwt, by William Oldfield (York) 1616.

Further illustrated information on the church is available at the church's web site on St. Oswald’s Church.

John Young Sargeant [1853-1918] of Greylands, Green Royd, Skircoat was for 25 years mill manager, and one of the representatives of the Halifax based wool moquette manufacturer

John Holdsworth & Co Ltd at their

Shaw Lodge Mills.

He died on 9th March 1918 aged 65 in Halifax after a period of illness, and was interred at

All Saints’ Church, Salterhebble after a service conducted by the Rev. F. O. Warman, Vicar of

Siddal.

He left a wife Mary Ann, and four daughters.

His obituary appeared in the local newspaper.

His position in the company was succeeded by Charles Sunderland, who at the time was serving in the army.

[Information, obituary and photograph provided by Carol Robinson, his great-granddaughter, in 2003.]

Scargill House

Kettlewell, Yorkshire

was purchased by

Clement Holdsworth from John Overend Wood in 1900.

Here he shot grouse on Conistone moor and fished for trout on the Wharfe.

After the early death of his wife

Mabel,

Scargill became the family home of

George Bertam Holdsworth and his three sons of whom

William was the lone survivor after the War.

After the war, Scargill was the home of

William where he remained until the sale of the property in 1957, when it became a Christian Holiday and Conference Centre.

See the page on Scargill House, Kettlewell

See Dobby, Dobby Loom.

See Birr Fabrics.

The Shaw House Estate - the property enclosed by Shaw Lane, Gaukroger Lane and Simmonds Lane, was bought by private treaty in 1871.

The land was sold to the local borough council in the 1960’s and a tower block was erected on the site.

Prior to its sale, the house was occupied by Dr. Joe Laycock, Patricia Mary (Paddy, née Holdsworth) and their family, Pat, Deidre and Gillian.

Shaw Lodge. The family home of

George Bertram Holdsworth

, located between the main Offices of

John Holdsworth & Co Ltd at

Shaw Lodge Mills, and

Spring Hall.

Shaw Lodge itself opened on 1 April 1917 as an annexe to the auxiliary hospital established at

Spring Hall.

The house became infested with woodworm, and was demolished in the early 1920’s.

(Bill Holdsworth, born in 1922, never knew the house.)

Shaw Lodge Mills - the site of the present complex of mills, and headquarters of

John Holdsworth & Co Ltd.

By 1830 John Holdsworth was joined by his four sons, William, George, Tom and John, and it was during their management of the firm in the 1850’s that most of the buildings, which are still in use, were erected.

The main weaving shed which is 240 yards long, bears the date 1852 and was constructed from stone excavated from the railway cutting which runs alongside the works.

To Shear is to cut the fleece from sheep. (Sheep Shearing)

To Shear is to cut loose or long fibres or tufts to uniform length after weaving. (Also known as to Crop or Cropping)

Shearing is the skewing of a fabric under stress, to check its

Dimensional Stability.

The Shears Inn, at Paris Gates, one of the most famous pubs in Halifax, is a quaint tavern or inn next to an ancient pack-horse bridge, “Boy’s Bridge” over the canal and the Hebble Brook.

It has one of the most unusual approaches in the business, along the cobbled streets in the shadow of Holdsworth’s

Shaw Lodge Mills complex.

In the nineteenth century this historic inn was the social spot for workers from the nearby mills.

In 1888 it was sold by Clement Holdsworth, owner of John Holdsworth & Co Ltd, along with the New Inn, Holdsworth Street, Lower Shaw Hill, Halifax, which closed in 1908.

It lies on the "Hebble Trail", a pedestrian and cycle route into Halifax along the course of the "Calder Navigation" from Salterhebble to Halifax centre.

The Hebble runs into the river Calder.

Today, the inn is a free house, provides excellent lunches at great value, and has a wide selection of real ales from which to choose.

Shed is an abbreviation for "Weaving Shed" which means the Weaving Department. It is usually used at Holdsworths in reference to the main weaving shed; A and B Sheds. The "Moquette Shed" is now known as "D Shed".

The Shed is also the term used for the opening formed when the warp threads are separated. This is the first of the three basic motions involved in weaving, (Shedding, Picking, and Beating-up.) Shedding is performed by the Shedding Mechanism, which can be driven by either a Cam-box, or a Dobby moving Heald Shaft or frames, or by a Jacquard lifting the threads individually.

Sheep are domesticated livestock - various usually horned ruminant mammals, raised in many breeds for Wool, edible flesh, or skin.

Any of various preparations of liquid disinfectant into which sheep are dipped to destroy parasites (organism that grows, feeds, and is sheltered on or in a different organism while contributing nothing to the survival of its host) and to clean their Wool, especially before Shearing.

In recent years the substances and the concentrations used have been altered to protect the environment, particularly regarding organophosphates.

A carrier for the yarn supply package (pirn or

cop) that is passed through the

shed to insert

weft during weaving.

For centuries handloom weaving had been carried out on the basis of the shuttle bearing the yarn being passed slowly and awkwardly from one hand to the other. In 1733 John Kay patented his flying shuttle that dramatically increased the speed of this process. Kay placed shuttle boxes at each side of the loom connected by a long board, known as a shuttle race. By means of cords attached to a picking peg, a single weaver, using one hand, could cause the shuttle to be knocked back and forth across the loom from one shuttle box to the other. A weaver using Kay’s flying shuttle could produce much wider cloth at faster speeds than before. Failure to get payment for the use of his idea and the destruction of his house in Bury by angry weavers, afraid that the new shuttle would destroy their livelihood, forced Kay to emigrate to France where he died a pauper.

In Face-to-Face weaving, on the power looms in use at John Holdsworths from 1940-1979, running at 80 picks per minute, the shuttles had to be changed by hand each time the weft cop or pirn ran out - this happened after every two minutes. The weaver stopped the loom, replaced the shuttles, and then replenished the empty shuttles then the loom carried on weaving. Experienced weavers could change shuttles in a couple of seconds each.

In wire-loom weaving, at the same period in time, most of the shuttle looms were fitted with

Northrop Automatic Pirn Changers, which replaced the nearly empty pirn in the shuttle from a

magazine or hopper without stopping the loom. Occasionally, if the pirn was not correctly inserted inside the shuttle, the shuttle could jam inside the cloth, of fly out of the cloth, resulting in a hole in the cloth, which was called a

Mullucks. (Spelling not confirmed!)

From 1972 on, all the new looms used weft insertion by

Rapier.

A loom in which the weft is inserted by means other that by a shuttle and is drawn from a stationary supply. The three usual types are Gripper-projectile, Rapier or Jet loom. At Holdsworths, all our shuttleless looms are rapier looms, using either carbon fibre fixed, or flexible rapiers.

The International System of Units (abbreviated SI from the French phrase, Système International d’Unités) is the most widely used system of units. It is the most common system for everyday commerce in the world, and is almost universally used in the realm of science.

In 1960, SI was selected as a specific subset of the existing Metre-Kilogram-Second systems of units (MKS), rather than the older Centimetre-Gram-Second system (CGS). Various new units were added with the introduction of the SI and at later times. SI is sometimes referred to as the metric system (especially in the United States), which has not widely adopted it, although it has been used more commonly in recent years, and in the UK, where conversion is only partial. SI is a specific canon of measurements derived and extended from the Metric system; however, not all metric units of measurement are accepted as SI units.

The true origins of the "metric system" date back to approximately 1640. It was invented by French scientists, and was given a huge boost in popularity by the French Revolution of 1789.

The most important unit is that of length: one

Metre was defined to be equal to 1/10 000 000th of the distance from the pole to the equator along the meridian through Paris.

The original base unit of mass in the metric system was the gram, but this was soon changed to the

kilogramme.

The unit of temperature became the centigrade or inverted

Celsius

grade, which means the mercury scale is divided into 100 equal length parts between the water-ice mixture and the boiling point of pure, distilled water. Boiling water thus becomes one hundred degrees Celsius and freezing is zero degrees Celsius. This is the metric unit of temperature in everyday use. A hundred years later, scientists discovered absolute zero. This prompted the establishment of a new temperature scale, called the absolute scale or

Kelvin scale, which relocates the zero place but still uses 100 kelvins between the freezing point and boiling point of water.

The metric unit of time became the second, originally defined as 1/86 400th of a mean solar day. The formal definition of the second has been changed several times for enhanced scientific requirements (astronomic observations, tuning fork clock, quartz clock and then caesium atomic clock) but wristwatch users remain relatively unaffected.

Sley :- The main moving part of a loom holding the

Reed; oscillating between the

Fell of cloth and either the

Heald Shafts or the

Jacquard Harness. Also known as the

Going Part.

Sley Over :- To thread the ends through the

Reed.

Jack Smith, born 28 April 1907 joined John Holdsworth & Co Ltd as a

Creeler

at an early age.

Jack served six and a half years in the RAF as a medical officer during the Second World War.

He was de-mobbed in 1946 and returned to the mill, in the

Weaving Department

and became the weaving manager.

Jack was one of eight children; his father died when he was six and his mother re-married and had two more boys (Ronald and ? Faulkes).

He was a keen gardener, and had a house with a large garden in Siddal. His daughter, Brenda Binns, still lives at a house which was built in that garden.

Jack’s son Stuart worked in the

Testing Department with Terry Wood, son of Stanley Wood, who worked in accounts department.

Stuart now lives in Harrogate.

The spinning process involves taking a textile fibre such asa wool, flax or cotton from its raw state through to the yarn state.

Spinning was originally done by the spindle and distaff. The distaff, a stick about 3 ft long, was held under the left arm, and the fibres of wool drawn from it were twisted spirally by the forefinger and thumb of the right hand. As the thread was spun, it was wound on the spindle.

The spinning-wheel was invented in Germany in the 1530s, consisting of a revolving wheel operated by treadle which drove a spindle. This method was unchanged until the time James Hargreaves invented the spinning-jenny in 1764.

In Holdsworth’s wool was spun under the Worsted system, using mainly ring-spinning and to a lesser degree, cap-spinning. (In man-made fibres, spinning is the process under which the filament is manufactured.)

The processes involved in preparing bobbins of yarn from Sliver are Gill Box, Autoleveller, Roving, Spinning, Twisting, Reeling, Dyeing, Winding. The collective term for these processes is Drawing.

The spinning department existed to provide most of the yarn for the company’s looms and managed to break even until the early 1970s.

The company could not afford to fund the re-equipping of both the spinning department and the weaving shed at the same time. The weaving shed had to take priority. In the autumn of 1979 John Holdsworth & Company therefore gave up worsted spinning after more than 150 years.

The process of joining together two ends of yarn, without a Knot by using fibre entanglement. This has the advantage of passing through yarn guides more easily and is less prone to damage or breaking, although if not performed correctly can be weaker.

A Split-Up loom is how we describe weaving two (or more) fabrics side-by-side in a loom. This is used when narrow width fabrics are required, as in the case for the London Transport Routemaster buses. Common widths manufactured being 22" and 28". Between the two fabrics a Monkey Chain is used to weave in a Leno which prevents the edge of the woven fabric from fraying. Nowadays, it is more common to make the material in a standard wide width and cut to size in the trimming stage od seat upholstery due to the economies involved.

Spring Hall, Skircoat, Halifax was part of the land accumulated over the years by

John Holdsworth. In 1857, the land was divided into four estates.

The estates were Shaw Lodge, where John Holdsworth himself had lived, Shaw Royd, Elm Wood and Spring Hall, each occupied by one of his sons.

It is located conveniently close to the company in its own grounds between

Elmwood and Shaw Lodge.

Spring Hall, which he had rebuilt to the designs of William Swinden Barber, a local architect was the home of

Tom Holdsworth until Tom’s death in 1881.

It was bought by the Midland Railway Company for use as a goods yard, but this plan was abandoned.

Served as a hospital for injured servicemen during the First World War.

In 1919, it was bought by J.H. Whitley as a guest house for his business associates, and he offered it for use as a guest house for young men until 1931.

In 1938 it was bought by Patons & Baldwins, for use as a sports facility for their employees then in 1948 donated it to the town.

The Percival Whitley Memorial Sports Hall was opened in 1959.

The Northern Ballet Theatre Company moved here for a short time in 1990.

Presently the building is in a sad state of repair, and the grounds are a recreational site, with athletics, tennis, crown green bowling, soccer and cricket regularly taking place.

Click here to see the page on Spring Hall, Halifax

Steam has played an important role in the running of John Holdsworth & Co Ltd since the earliest of days.

In yarn processing, for example, steam is used to relax the yarn after

Twisting, in order to remove the tendency of the yarn to untwist itself, having its own stored energy.

In Finishing the fabrics, again steam takes out any creases, and relaxes the twist in the tufts in order to produce a better

cover with less openness, revealing the back of the cloth grinning through.

Until the mid-nineteenth century, steam was also used for power transmission through

Mill Engines, of which Holdsworths had a number.

In addition, steam was also used as the means by which the buildings were heated. This was not an efficient process, but as

Coal

was cheap, it was not a matter of concern at that time.

See also related topic -

Gas Retorts which were used to make the coal gas for lighting.

Throughout his lifetime, Harry Straker was involved in the manufacture and design of moquette, following in the footsteps of his father. (He was christened at St. Peter’s, the small Saxon church in Hartshead, where from 1810 to 1815 Patrick Bronte, the father of Charlotte Bronte was the Vicar, and which stands very close to Kirklees Priory, seat of the Armytage family and the legend of “Robin Hood”.)

Harry's greatest skills were in designing and technical drawing; he just performed this freehand, which he learned during his period of service in the Royal Air Force, when he was involved in designing aircraft.

After spending a lifetime in the moquette industry, in England at Listers of Bradford; at British Furtex Fabrics Ltd in ~1975-8, in Ireland 1982-3 at Birr Fabrics, (when he penned "Overlookers and Fitters Manual for Wilson & Longbottom Wire Looms") and then later Iran and Turkey, with Leslie Hincliffe and Colonel Crowther, Harry joined John Holdsworth in his 65th year in 1988. Harry adopted the best possible techniques to improve the products and the processes and he played a major part in building up the most modern plant of its type in the world. He played a pivotal role in the take-over of Firth Furnishings in Heckmondwike, and Birr Fabrics in 1992.

Harry Straker commanded great respect as a kind and caring man who was always willing to share his knowledge and encourage others. He retired through ill health at the age of 75 in 1998, and died shortly thereafter, leaving his wife Ivy and son.

Charles F. Sunderland joined the

Holdsworth company when he was a boy.

He was appointed a representative whilst serving in the army in March 1918 on the death of

John Young Sargeant.

Charles Sunderland became the London manager, and was transferred to Halifax as general manager in 1945.

He became a director of

John Holdsworth & Co Ltd.

In February 1949, he was proposed for re-election as a director by

Bill Holdsworth but instead, announced his intention to retire from the business altogether.

His son

Philip became manager of the firm’s London branch.

Philip Sunderland, the son of

Charles, was born in Halifax and joined John Holdsworth & Co Ltd straight from Crossley and Porter School, Halifax in 1928.

Philip’s connection had generally been concerned with sales and promotion, following his father’s footsteps.

For 16 years after the Second World War he was the manager of the firm’s London branch before joining the board in 1962 as sales director.

Married to Marian, with one daughter, he was president of Halifax Chamber of Commerce in 1973.

He died suddenly at

Shaw Lodge Mills in September 1975.

His position was succeeded by

Raymond Sutcliffe.

James Sutcliffe & Sons Ltd, suppliers of dyed cotton for warps were situated at Victoria Mills, Greetland, Halifax.

Run by brothers, Peter and Cedric Whiteley, the firm closed in 198? and the premises were acquired by Andy Thornton International Antiques.

Malcolm Sutcliffe joined John Holdsworth & Co Ltd in November 1979 as a Wire-Loom weaver having previously worked in the carpet industry at Dean Clough, in Halifax.

Malcolm subsequently gained experience as a weaver on Jacquard and Shaft double-plush looms with great success, and before long was promoted to supervisor.

In 1992 Malcolm became manager of the

Weaving Department.

In 1998, following a restructuring in the company, Malcolm

moved into the

mending and finishing department as the head supervisor.

Malcolm married Heather, and they had two daughters. A number of Malcolm’s immediate family also worked in the business, including his sister Marjorie Baird (winder), his brother-in-law Keith Baird (winding supervisor), and his daughter Lucy Sutcliffe (sales team).

Malcolm Sutcliffe Scott Taylor, Peter Rosier, Karl Lakey Ladyship Mills, Mar 2000 |

Malcolm Sutcliffe Finishing Room Shaw Lodge Mills Nov 2000 |

Malcolm Sutcliffe Lean manufacturing seminar Warwick, Feb 2003 |

Raymond Sutcliffe, born 30th October 1918, joined John Holdsworth & Co Ltd on 23 November 1933 and became an experienced and long-serving sales representative. He became sales director in 1977, succeeding Philip Sunderland. Raymond retired in December 1981, and was succeeded by Ernest Hirsch, his opposite number from Firth Furnishings, the company’s main competitor.

A swift is a device which has an expanding core that can be adjusted to fit various sizes of Hank, Skein, Reel, in order to help keep the hank of yarn under control while unwinding it. There are two main kinds of swifts: the umbrella swift and the squirrel cage swift.

|

©

2025

David W. Holdsworth |

|

Please send questions, updates, additions to: |