The world of Jacquard weaving was a very different place until the 1980s. Jacquard weaving machines used mechanical Jacquard heads and were slow and cumbersome. Jacquard designs were stored on paper or cardboard card sets. Pattern preparation was tedious and inefficient, and the acronyms CAD and CAM were unknown to Jacquard designers.

In the Design Department the traditional Jacquard designing process started with the conversion of a sketch or design concept into a "point paper" rendition of the pattern. Point paper is a special type of grid paper with various sizes of grids, representing either the warp and weft yarns of a flat-woven fabric, or the tufts of a pile fabric. The point paper designer painted a new version of the pattern pixel by pixel within the point paper grid lines. A limited number of colours were used, each representing a weave effect, or a frame of pile yarn. Complex designs required several days of painting before the point paper was complete.

After the point paper was completed, it was turned over to the card cutting department. A card cutter read the point paper line by line and then translated it into a Jacquard card set using a mechanical card punch machine. Operation of the card punch was difficult to learn and unforgiving. Errors were repaired by taping and repunching the cards. Production of a Jacquard pattern from the start of the point paper painting process through to the production of the Jacquard card set often required at least a week of time.

The Jacquard weaving industry has greatly benefited from tremendous advances in technology between 1980 and the present. Early products automated the task of reading point paper sketches in much the same way that word processors automated the process of typing documents. A computer automatically created pattern repeats. Errors could easily be corrected before the cards were punched. Patterns and weaves could be stored on floppy disks, rather than on paper. An average Jacquard pattern could be processed 3 times more quickly using an early computer system than with the best electro-mechanical card punching machines available in the 1970's.

ITMA

ITMA

At the Milan International Textile Machinery Association (ITMA) exhibition in 1983, was introduced a truly revolutionary system. This system allowed Jacquard designers to scan their sketches with a digital camera and create their "point paper" layout directly on the computer's screen. Creating point paper on the computer screen was a big time saver because parts of the image could be easily moved, repeated, or corrected. After the design was completed on the computer screen, it did not need to be read by a card cutter. After a few simple assignments the design could be transferred from the computer screen onto punch paper. Use of this system reduced the time necessary to create a Jacquard pattern from days to hours.

Today, the advent of CAD/CAM and electronic Jacquard machines has revolutionised and revitalised the Jacquard weaving industry. CAD/CAM systems have become a necessity rather than a luxury for Jacquard studios.

Designer at CAD workstation

Designer at CAD workstation

CAD systems were introduced to Holdsworths in the late 1980s. At this stage they were basic, but still managed to provide huge productivity gains in the design process by eliminating the need for the painstaking, meticulous and repetitive work colouring the tiny spaces on

point-paper which was used by the

card-cutter to punch the cards for the

Jacquard, and by a technical designer to prepare the

plant-sheet. They also allowed the designer to make alterations after initial samples without a great deal of effort, thereby increasing flexibility and reducing response times. These systems have been further developed since that time and now include simulation software, which enables the designer to preview the interior of a vehicle in virtual reality, realistically showing textures and shadows, and change the seating material, curtains, and colours at the touch of a button. Today this facility is being rolled out so that customers can experience this for themselves from the comfort of their own office or home.

This technology advanced the communications inside the business as well, to the extent that the designer could download their creation directly to the loom, where the electronic Jacquard enabled the loom to commence production immediately.

A Cam is a turning or sliding piece which, by the shape of its periphery or face, or a groove in its surface, imparts variable or intermittent motion to, or receives such motion from, a rod, lever, or block brought into sliding or rolling contact with it.

A Cam Box is a mechanism on the loom which performs the Shedding. Limited by the cams to 1:1 plain weave or simple 2:1 and 2:2 Twill weaves, cheaper than a Dobby, they are used where only simple weaves are required, such as the ground structure on Carpet and Moquette.

In October 2007, the business of John Holdsworth & Company was bought by the Camira Group of Mirfield; the property remaining in the hands of Hanson Partners. Production continued until August 2008 at Shaw Lodge Mills as Hebble Valley Weavers. It was intended that Shaw Lodge Mills would be redeveloped and production would be moved to another site in Calderdale and eventually overseas to Eastern Europe or Asia.

Carding is a process in the preparation of staple fibres (wool and cotton) for spinning into yarn. The fibres are teased into a parallel orientation by card-wire, and then formed into a sliver which is drawn through a gill-box prior to roving. The carding machines were large, noisy and dangerous.

One of the world's major carding engine manufacturers, Crosrol, was set up by a Hungarian, Mr André Varga [1893-1998] in the 1940s and based at Pellon Lane in Halifax, moving to a 220,000 sq.ft factory on the Holfield industrial estate in the 1980s. Crosrol was one of the world's major designers, manufacturers and suppliers of opening, cleaning, blending and carding machinery for the short-staple fibre industry, especially for cotton spinning and nonwovens, including surgical products.

The Company was responsible for almost every major development in short-staple carding during the half-century of its operation - a period in which the technology of short-staple preparation advanced dramatically. It won the Queen's Award for Export Achievement in 1995, and the Textile Institute Jubilee Award (for successful research and invention) in the same year.

The company exported to over 60 countries, and closed with the loss of more than 300 jobs in the year 2001.

David Bradley

demonstrates Card Stamping

David Bradley

demonstrates Card StampingCard Cutting or Card Stamping is the process of punching holes in Jacquard cards, following the designer's instructions which are set out on point paper.

This is a highly skilled art, and takes many years of practice to become proficient.

Key people in this area of the business since 1915 have been Edward Crossley, Ernest Edmund Jennings, Bill Sharp, Donald Halstead, (who served the company 50 years) and David Bradley, son of Derek Bradley.

See the page on Jacquard Card Stamping.

Floorcovering material made from textiles, usually with a surface effect to give depth. Manufactured traditionally by weaving, using mainly wool fibres, underwent a transformation in the 1970s with the introduction of cheaper yarns (acrylic, nylon, polyester and polypropylene) and cheaper manufacturing methods (tufting and bonding, then printing.)

Machine woven carpets are one of two main types - Wilton or Axminster. Axminster carpet comes in two versions, Spool Axminster and Gripper Axminster. Both, Axminster and

Wilton, can be produced in large complex patterns and in a number of colours.

In March 1924

George B Holdsworth bought Catteral Hall in Giggleswick, with his wife

Mabel

and this remained their principal home from 1924 until her death in August 1932.

George moved to

Scargill House,

Kettlewell and Catteral Hall was sold in 1933.

Centigrade is a unit of measure for temperature, related to

SI Units. In the International System of Units (SI) is the

Kelvin (K).

Temperature is the physical property of a system which underlies the common notions of "hot" and "cold"; the material with the higher temperature is said to be hotter.

Edmund (Eddie) Chapman was head designer at

John Holdsworth & Company Ltd.

The earliest of his designs held in Holdsworth archives dates from 1918, and the latest from 1958.

Even after he was succeeded by

Isaac Jennings, he continued to work in the

design department.

He was wounded during the First World War, with an injury to his leg, and walked with a stick since then.

Edmund was godfather to

EE Jennings, who worked in the card cutting, and also the design department during the Second World War.

See photo, right, of EE Jennings (boy), Eddie Chapman (in beret) and EEJ's parents (Alice and

Isaac Jennings) at Cambria where

Ernest Edgar Jennings fell.

Gareth (Gary) Charles was appointed the finishing manager at John Holdsworth & Co Ltd. in October 2004. Gary's responsibilities included the mending and finishing departments as well as warehousing and despatch functions.

The process of removing weak/thin places or other imperfections such as thick knots or slubs from a Yarn, usually during a Winding process.

Cloth is the term for most textile fabrics. Originally applied to wool cloth suitable for clothing.

Cloth Roller The roller onto which cloth is wound during weaving on the loom. In modern high production machines these can be replaced with

A-Frames.

The mill premises of John Holdsworth & Co Ltd are located immediately next to the route of the Halifax Branch Canal which joins the Calder and Hebble Navigation Canal at Salterhebble. It was along this canal in the nineteenth century that horse-drawn barges carried coal to the Company's boiler house and gas works in order to generate the Steam which was required to drive the Mill Engines, as well as to provide space heating in the buildings. Coal was also used by the Company to produce Coal Gas. This was used for the indoor lighting. Within the premises today are the unique remains of Gas Retorts, benches and storage tanks, which we believe to be an important heritage site.

To rectify a cloth which has been defectively processed.

A defect in winding that leaves some yarn in straight lengths across the end of the bobbin or cheese. It is caused by the yarn guide passing beyond the traverse length for the bobbin. It can cause yarn to break during unwinding.

Terry Colbert joined the company as a sales representative, to work under Ernest Hirsch. His background being in marketing. He joined the board in 2000 as sales director. Terry left Holdsworths in November 2000 to take up a similar position in a knitting upholstery manufacturer.

The visual appearance of an object caused by the light emitted by, transmitted through or reflected from an object, which depends on the spectral composition of the light, and the response of the observer. It can be partly described in terms of Hue, saturation and lightness or by reference to standards. e.g. Munsell Colour Atlas, Pantone etc. With increased use of PC screens, colour is often described in RGB (Red, Green, Blue) or in printing, CYMK (Cyan, Yellow, Magenta, blacK) values, however the appearance also depends on the screen characteristics, lustre etc.

Colour Constancy is the ability of an object to give the same colour impression when viewed under different lighting conditions. e.g. under daylight, tungsten filament light and fluorescent light.

Colourfastness is the degree of resistance to fading of a Dyed material, usually against light, measured on a scale of 1-8. 8 being the most resistant. It is also measured against rubbing, washing etc. See Crocking, Crockmeter.

The board which separates the harness cords just above the Fell of cloth. Usually built in sections to allow for different widths of cloth, these can also be formed by an arrangement of glass rods.

The process of straightening fibres, removing short fibres using a series of combs, nips, rollers and brushes. This is particularly important to the worsted (compared with the woollen) method of processing wool.

The landmark stages in the development of Information Systems at John Holdsworth's.

1979 Stand-alone computer used for analysing production information, and for payroll.

1985 First networked computers installed; Apricot computers on Omninet, later Arcnet and eventually ethernet network, for spreadsheet and document processing.

1986 DEC PDP-11 minicomputer installed for manufacturing, with bespoke software.

1994 Business system (Systex) installed on HP Unix computer.

1995 Integrated CAD system installed. email installed, website set up.

1999 Business system transferred from mainframe to servers and thin clients.

The amount of moisture present in a textile material. To allow the material to stabilise with its surroundings, or to alter the moisture content of the material. The properties of some textiles are very dependent on the moisture content, so in order to carry out testing, say for strength, it is necessary to ensure that the material is at a standard condition, or

Regain.

See also Absorbency.

S.I. No. 251/1963: CONDITIONS OF EMPLOYMENT (MOQUETTE WEAVING INDUSTRY) (EXCLUSION) REGULATIONS, 1963

The Conditions of Employment Act, 1936, provided that persons under 18 years may be employed in industrial work between the hours of 8 am. and 8 pm. only. The purpose of these regulations was to permit the employment of persons over 16 years between the hours of 6 a.m. and 10 p.m. in the moquette weaving industry.

The conical support onto which cones of yarn are wound. The yarn package wound onto a conical shaped former. The advantage of using cone rather than cheese packages is that cones can be unwound faster over-end by reducing the balloon size with balloon-breakers. In Holdsworth's all yarn is processed in cone form, until it is finally wound onto Bobbin/Cheese for the looms.

The CBWT is the voice of the wool textile industry; the body which represents wool textile manufacturers.

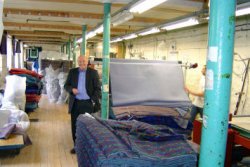

The Contract Department is the location where the rolls of moquette were measured and packed ready for despatch.

This is part of the Mending and Finishing departments.

The origin of the name is in the large railway contracts against which cloth was stored awaiting inspection by the railways' appointed inspector, prior to being despatched to the rail depots in large batches.

John Birtwhistle & his father, Robert Birtwhistle Contract Department, 1948 |

John Birtwhistle pays a visit Contract Department, 2007 |

A cop or

pirn is a form of yarn package such as is spun on a mule spindle, that is essentially self-supporting. A weft-cop, as used at Holdsworth's on

Face-to-Face Looms until 1980, was a cop of tightly wound yarn, wound on itself with no tube, of such a size that it could be loaded in the loom

shuttle. These cops were very difficult to handle without damaging them, and encountered a great deal of problems, in terms of waste material and the maintenance cost of the cop-winders; they became obsolete with the replacement of machinery with shuttle-less looms made by

Güsken in the early 1980s.

However the

Wilson and Longbottom

wire-looms, of which some remained in production at Holdsworth's until the year 2005, used a

Shuttle and weft

pirn as shown in the photograph on the right.

These looms were fitted with the

J.H. Northrop automatic pirn replacing apparatus requiring no operator intervention to replenish the weft other than loading the rotary hopper or magazine with full weft pirns.

These pirns were wound on a Gilbos pirn winder.

1. Any of various shrubby plants of the genus Gossypium, having showy flowers and grown for the soft, white, downy fibres surrounding oil-rich seeds in the

Boll.

2. The fibre of any of these plants, used in making textiles and other products.

3. Thread or cloth manufactured from the fibre of these plants.

4. The crop of these plants.

5. Any of various soft, downy substances produced by other plants, as on the seeds of a cottonwood.

In Holdsworth's cotton yarn is only used for the ground structure in moquette; the pile is made from

Wool.

For more information, see the item on

fibres.

The method of describing the thickness, or mass per unit length of a yarn. (In America, the term Size is used.) There are many systems which have been used over the years, both direct and indirect systems.

Direct systems, which are based on the number of mass units per unit length include

Tex (gram/kilometer) and

Denier (gram/9-kilometer).

Indirect systems are based on the number of lengths per unit mass.

i.e. Worsted Count (560 yards), Cotton Count (840 yards) and no less than nine different Woollen Counts.

(For example, a 16's Worsted Count Yarn is such that 16

Hanks of 560 yards will weigh one pound. The Cotton Count is the number of hanks of 840 yards per one pound weight.)

The degree to which the backing of the cloth is concealed behind the pile in a pile fabic. (It can also describe the openness - the degree to which light can pass through the cloth.)

The increase in the number of picks inserted per unit length of a woven cloth, by reducing the Take-up for short periods of time.

A creel is a frame, on which there are pegs which hold the

Bobbins which are needed to supply the loom with

Pile yarn.

At Holdsworth's, each creel hold up to 4,000 bobbins.

A creeler is a person employed in carrying out creeling, which is the process of tying new boobbins into, or replenishing a Creel.

Crocking is the transfer of colour from one cloth to another by the action of rubbing.

The Crockmeter is the instrument used to measure this, which is one of many tests used to measure

Colour Fastmess.

See Shear, Shearing.

A 1953 Penny

A 1953 Penny

In 1850 the coinage used was based on a system 1,000 years old. Victorian silver coins were made of silver unlike the cupro-nickel coins of today. A Pound was a good deal of money. The average annual income was just £20. There were of course those who were much richer and some very poor. The sign of being middle-class was having at least one live-in servant and at least £300. An income of £1,000 per year would have kept you in considerable luxury. A vicar would earn as little as £50 a year, and a clerk £150.

A gold coin worth one pound was called a Sovreign, but only a quarter of the British population would have handled such a coin in their lifetime. Paper money for larger denominations would be almost unheard of. Wealthy people handled their purchases by credit; settling their accounts at the end of the month. A gentleman would not have been seen exchanging money; he would have goods made to order. A Guinea was considered to be a more gentlemanly amount than a pound. Tradesmen were paid in Pounds, whereas gentlemen such as artists were paid in Guineas.

A 1957 Halfpenny

A 1957 Halfpenny

The Victorian Pound consisted of 240 Pennies; a Penny was written (1d) where d is derived from the Roman coin denarius. The penny was divided into 2 Half-pence (pronounced haypence) or 4 Farthings. Other coins in common use were the threepenny bit (3d), the sixpence (6d) (Tanner), the shilling (1s or 1/-) (Roman coin solidus) (Bob) which was worth 12 Pennies, and the Half-Crown (2s6d or 2/6) worth one eighth of a Pound. The seated figure of "Britannia" was seen on the reverse of the penny, halfpenny and farthing, and she appeared on coins issued under the Roman emperor Hadrian. Britannia was the Roman name for Britain.

In 1849 the Victorians introduced a new coin, the Florin worth 2 Shillings or 1/10 Pound. This was commonly called the two shilling piece or two-bob-bit. It was minted for 120 years when in preparation for decimalisation it became the new ten-pence piece. The silver sixpence was withdrawn in 1980.

A 1948 Farthing

A 1948 Farthing

It was apparent that inflation meant that by 1956 the farthing had outlived its usefulness, and minting ceased after that year. The farthing ceased to be legal tender after 31 December 1960.

The halfpenny coin ceased to be legal tender after 31 July 1969, although proof coins were produced, dated 1970, for the cased proof sets bidding farewell to the old currency. The new Two Pence coin, introduced when decimalisation of British coinage took effect in 1971, is essentially the same size as the halfpenny coin as it had most recently existed.

Threepence

Threepence

The brass threepence ceased to be legal tender after 31 August 1971.

Decimalisation took place in 1971. Post-decimalisation, "shilling" referrs to the 5-pence coin, which is still worth 1/20th of a pound (because there are now 100 pence in a pound). The name shilling is believed to come from old Scandinavian skilling, meaning a division, or a mark on a stick. Shillings (and five-pence pieces) were finally withdrawn in 1990, when a new, smaller, five pence coin was introduced.

The overlapping scales which form the outer layer of animal hair Fibres.

To layer fabric in folds, at full width. See Plaiting.

|

©

2025

David W. Holdsworth |

|

Please send questions, updates, additions to: |